|

The Forrester Wave™: Supplier Value Management Platforms, Q3 2024 See Report

Blog »

Procurement in the Age of Uncertainty: 4 Lessons from the New Forrester Study

by Alex Saric

In today’s age of uncertainty, procurement departments are under tremendous pressure. As the lynchpin to suppliers, they play a pivotal role in combatting the effects of inflation, ensuring supply continuity, complying with regulatory requirements, improving sustainability and other top business priorities. Such broad priorities require new supplier strategies, new information and a delicate balancing act between competing objectives. Furthermore, their rapidly shifting nature requires a new level of agility. Survey results in a new study by Forrester, commissioned by Ivalua, reveal several important lessons for procurement leaders to keep in mind as they adapt their departments for success.

1. Collaborate to Win

Henry Ford’s quote that “coming together is a beginning, keeping together is progress, working together is success” has never rang more true. Being more agile and addressing more strategic objectives requires procurement to be more collaborative. Protecting profitability in the face of inflation isn’t about squeezing suppliers in negotiations, but working together to find ways to reduce costs in the full value chain. Ensuring supply continuity requires timely and open sharing of information. The biggest gains in sustainability typically come from working with suppliers rather than finding new ones.

The same applies internally. Procurement must align on goals and expectations with internal stakeholders and ensure alignment on priorities for when trade-offs are required.

That said, collaboration is one of those principles that people feel compelled to agree is good. Yet making it how you do business is another thing altogether. Fortunately, the report shows that procurement is putting actions behind words. 78% engage suppliers more collaboratively than they did 3 years ago. 50% have increased collaboration & information sharing with suppliers in the past year. 45% collaborated with suppliers to launch new products. 30% are applying supplier collaboration as a top strategy for combatting the effects of inflation.

There are 3 keys to success when it comes to enabling scalable, effective collaboration. The first, as is so often the case, involves people – ensuring procurement KPIs are aligned with a collaborative approach. They should reflect the various strategic objectives procurement can support to incentivize the right behavior. The next two involve technology. Technology must be employed that supports securely sharing all relevant information between internal stakeholders and suppliers, and it must support effective planning and transparency for project teams. That must span the full breadth of information required throughout the product and supplier lifecycle, from product design details to planned orders and forecasts. This is a key reason for the shift towards a core platform for spend/supplier management – collaboration needs to be embedded in Source-to-Pay processes and it does not stop and end with any one process.

Automotive parts leader Meritor presents a great example, having digitized the full supplier and product lifecycle to improve collaboration and accelerate the launch of new products.

2. Take Control of Your Supplier Data

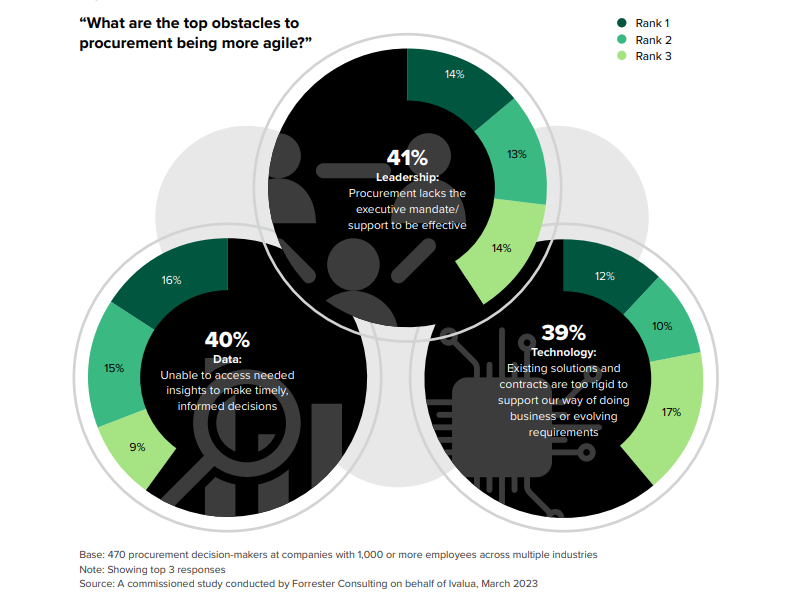

Dealing with so many objectives and changing conditions requires more information than ever before, particularly regarding suppliers. Yet it remains a fundamental problem. More respondents listed not being able to access the insights needed to make timely, informed decisions as their top obstacle than any other.

It is also a major risk. 76% admitting to compromising supplier due diligence in the past year for supply continuity and 73% compromising performance on other objectives. Without sufficient data, you end up making unknown and sometimes unnecessary compromises, exposing organizations to other risks.

More than half of procurement departments are taking action by investing in technology solutions to efficiently manage supplier information and mitigate risk. However, to reap the expected benefits, it’s essential to implement these solutions effectively.

First, be sure to leverage any technology investment as an opportunity to unify supplier data rather than create yet more silos. Look for unified data models, where new information is instantly linked to the same record instead of different records in different parts of the S2P process which then have to be mapped in a separate data layer. That ensures accuracy, timeliness and better accessibility regardless of where a user is working.

Second, map your sub-tier. Disruptions, ethical and compliance risks are more likely to occur deep in your supply chain. Technology can help scale collecting of that information and visualizing interdependencies. Companies are often surprised on how exposed they are to specific sub-tier suppliers that supply multiple immediate suppliers.

Lastly, don’t waste a S2P digitization initiative opportunity to address existing issues such as duplicates in your back-end systems. Some suites have embedded MDM capabilities that can unify data across the enterprise and fix issues at the source. Chassis Brakes Int’l (now part of Hitachi), presents a great example, having unified supplier data across all 25 global ERP environments through it’s global Source-to-Pay (S2P) platform. The permanent transparency helped drive a rationalization of its supply base to improve performance, relationships and deliver savings and lower risk.

3. Embrace Agile Technology

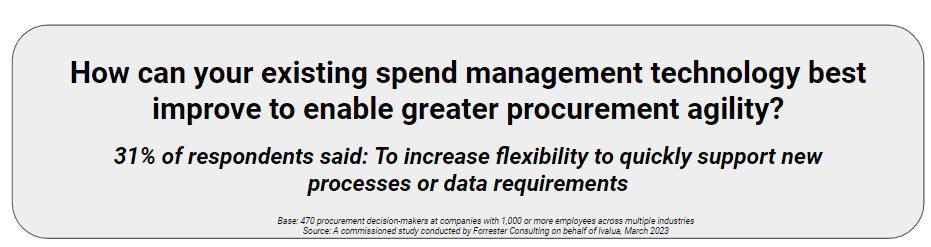

Agility isn’t simply required of procurement professionals today – technology must be as agile. Forrester found that the number one way spend management technology needs to improve to support procurement today is to increase agility to support new processes or data requirements.

It is essential that leaders consider such flexibility when evaluating technology to avoid making decisions that may support today’s requirements but become obsolete and reduce agility tomorrow. This is a particular risk, rarely discussed, with cloud-based solutions. While offering faster time to value and easier maintenance, many are rigid. Avoid that compromise by leveraging cloud-based solutions that have sufficient ability to adapt to tomorrow’s unknown requirements.

Look at the data model. For example, can the system support capturing new data requirements if regulations change? That may entail more than a new field or two but a table of entirely new data. And can that data simply be reported on or can it be incorporated into the user and supplier interface and into intelligent workflows (ex. determining approval flows or which products appear in a user’s catalogue)?

Also consider processes. Can a system easily adopt to new processes or does it require changes to the vendor’s roadmap or costly consultants/customizations? During the Covid pandemic, the City of New York had to adjust their extensive new supplier onboarding process to enable rapid enablement of new suppliers of N95 masks. There would have been no way to do so in time within their digitized process if they needed consultants or product enhancements.

4. To Thine Own Self Be True

For the final point, I’d like to focus on a warning. Driving improvements in any of the above areas, or others for that matter, requires an honest, accurate assessment of your starting point. Unfortunately, a consistent theme in surveys of procurement leaders in recent years has been a staggering level of overconfidence, and this survey proved no different regardless of the industry, seniority or region. 73% of the 470 respondents spanning 9 countries across North America, Europe and Asia felt they outperformed their competitors across the top priorities in the past year. The remaining 27% felt they performed in line. Not one felt they performed worse than competitors.

Statistically, this is virtually impossible to be true. The risk is that overestimating one’s own current performance reduces the pressure to change. Additionally, there is likely a lack of understanding of what is possible. Both can lead to placing your business at a competitive disadvantage. It also risks the department’s stature within the organization as surveys of other functions consistently present a less rosy view of procurement’s performance.

Volatility is the word of the day and unfortunately should be expected to persist for the coming years. This presents both a challenge and opportunity for businesses and procurement. Forrester’s latest survey shows promising signs of procurement improving it’s ability to enable organizational agility, but also warnings. Savvy leaders will heed the lessons to raise procurement’s stature while helping build a competitive advantage for the business.

To download the full report, click here.

Alex Saric

Chief Marketing Officer

Alex has spent over 15 years of his career evangelizing Spend Management, shaping its evolution and working closely with hundreds of customers to support their Digital Transformation journeys. As CMO at Ivalua, Alex leads overall marketing strategy and thought leadership programs. Alex also spent 12 years at Ariba, first building and running the spend analytics business as General Manager. He then built and led Ariba’s international marketing team until successful acquisition by SAP, transitioning to lead business network marketing globally. Earlier, Alex was a founding member of Zeborg (acquired by Emptoris)where he developed vertical Procurement applications. He began his career in the U.S. Cavalry, leading tank and scout platoons through 2 combat deployments. Alex holds a B.S. in Economics from the U.S. Military Academy at West Point and an international M.B.A. from INSEAD.

You can connect with Alex on Linkedin