Supplier Lifecycle Management (SLM) is the holistic process of managing supplier interactions and relationships from inception to conclusion. It spans the complete spectrum of engagement, starting with the supplier discovery and onboarding, weaving through continual performance assessment, and extending to the critical juncture of contract renewal or termination.

A well-orchestrated SLM strategy emphasizes streamlined and transparent onboarding procedures, robust performance tracking systems, fostering of strong supplier partnerships, meticulous risk mitigation, supplier relationship management, vendor management, strategic contract administration, and an unwavering commitment to ongoing improvement and supplier capability enhancement.

Gartner predicts that nearly 6 in 10 organizations are planning to reinvent their supplier lifecycle management process in the next three years, as they prepare to face existing and upcoming procurement challenges. By implementing robust Supplier Lifecycle Management practices, organizations can optimize supplier relationships, mitigate risks and maximize the value derived from supplier partnerships.

In this article, we’ll provide valuable insights into supplier management strategies, processes, SLM technology and best practices involved in effectively managing supplier relationships throughout their lifecycle.

Let’s Start With SLM: What Is Supplier Lifecycle Management?

Supplier Lifecycle Management (SLM) refers to the process of managing suppliers throughout their entire engagement lifecycle, from identification and selection to onboarding, risk and performance tracking and offboarding. Two primary areas impacted by supplier lifecycle management are the Procure-to-Pay (P2P) and Source-to-Contract (S2C) cycles. Let’s look at a couple definitions:

Procure-to-Pay encompasses the entire purchasing process, starting from the identification of a need for goods or services within the organization and continuing through to the final payment to the supplier. The procure-to-pay process involves various steps such as requisitioning, approval workflows, supplier selection, purchase order creation, goods receipt, invoice processing and payment. The P2P cycle focuses on streamlining transactional activities, ensuring compliance with procurement policies and optimizing the purchasing process to drive efficiency and cost savings.

Source-to-Contract involves the sourcing and negotiation phase of procurement, beginning with identifying sourcing requirements and culminating in the execution of supplier contracts. The source-to-contract process comprises activities such as supplier identification, market research, request for proposal (RFP) or request for quotation (RFQ) issuance, supplier evaluation and selection, contract negotiation and contract execution. The S2C cycle aims to identify strategic sourcing opportunities, leverage supplier relationships, negotiate favorable terms and establish contractual agreements that align with organizational objectives.

Both Procure-to-Pay and Source-to-Contract cycles are integral components of the procurement process, each focusing on different stages and objectives to ensure efficient acquisition of goods and services while minimizing risks and maximizing value for the organization.

What is Supplier Lifecycle Management Software?

Supplier Lifecycle Management (SLM) software is designed to automate and streamline the management of supplier relationships throughout their entire lifecycle. Typically, it’s a centralized platform for managing various stages of supplier engagement – identification, selection, onboarding, performance tracking, risk management and offboarding.

SLM software enables efficient onboarding processes by automating supplier registration, qualification and approval workflows, ensuring compliance with regulatory requirements and organizational standards. It also provides tools for tracking and monitoring supplier performance against predefined key performance indicators (KPIs) and service level agreements (SLAs), enabling organizations to assess supplier performance in real-time and take proactive measures to address any issues.

Supplier management software helps organizations mitigate risks associated with suppliers by assessing risk profiles, conducting due diligence and monitoring compliance. It also offers features for managing supplier contracts throughout their lifecycle, from negotiation and execution to renewal and termination, and centralizes contract document storage.

Key features of supplier lifecycle management software can include:

- Supplier Onboarding: Streamlined processes for supplier registration, qualification and approval workflows.

- Performance Monitoring: Tools for tracking and evaluating supplier performance against predefined KPIs and SLAs.

- Risk Management: Features for assessing supplier risk profiles, conducting due diligence and monitoring compliance.

- Contract Management: Centralized repositories for storing and managing supplier contracts throughout their lifecycle.

- Collaboration and Communication: Tools for facilitating communication and collaboration between stakeholders involved in supplier management processes.

- Data Analytics: Capabilities for analyzing supplier data to identify trends, opportunities and areas for improvement.

- Document Management: Secure storage and retrieval of supplier-related documents, such as certifications and contracts.

- Audit Trails: Traceability and accountability features to track changes and actions taken within the system.

- Integration: Seamless integration with other systems and enterprise applications for data exchange and workflow automation.

- Reporting and Dashboards: Customizable reporting tools and dashboards to provide insights into supplier performance and compliance.

Download Ivalua’s Supplier Management Datasheet

Why Is Holistic Supplier Management Important?

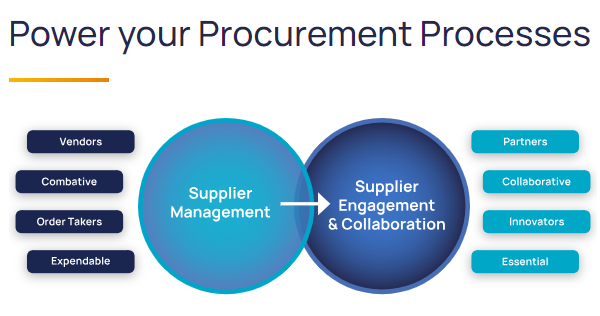

Effective supplier management is pivotal for an organization, as it ensures a cohesive approach that can lead to cost reductions, innovation, and competitive advantage by optimizing processes and elevating supplier contributions.

By adopting a sophisticated SLM approach, organizations unlock the potential to create a sustainable and mutually prosperous ecosystem, where both they and their suppliers thrive on the tenets of collaboration, efficiency, and excellence.

The Hackett Group’s 2022 Supplier Relationship Management Study, Supplier Relationship Management (SRM) involves proactive and coordinated efforts to manage suppliers effectively. This encompasses several key objectives, including enhancing supplier performance management, mitigating risks associated with supplier relationships and leveraging supplier capabilities to trigger internal business processes, such as innovation. When supplier management operates independently from other procurement processes, it only captures a fraction of its potential value.

Watch this webinar to learn more about what is covered in Hackett Group’s report.

The 8 Stages of The Supplier Lifecycle Management Process

The Supplier Lifecycle Management Process consists of eight stages, each playing a crucial role in managing supplier relationships:

- Identify Suppliers: This initial stage involves the identification of potential suppliers based on specific criteria such as product or service offerings, capabilities, geographic location and compliance requirements.

- Select Suppliers: Following the identification of potential suppliers, a meticulous selection process ensues to evaluate and choose the most suitable candidates. Factors considered during this process may include price, quality, reliability, past performance and alignment with organizational values.

- Onboard Suppliers: Once suppliers are selected, the onboarding process starts. This entails establishing contractual agreements, setting up communication channels, sharing relevant information and ensuring compliance with legal and regulatory requirements.

- Manage Performance: After suppliers are onboarded, their performance is continuously monitored and evaluated. Key performance indicators (KPIs) are established to assess factors such as delivery timeliness, product quality, customer service and adherence to contractual obligations.

- Keep Accurate Supplier Data: Effective Supplier Lifecycle Management (SLM) hinges on accurate supplier information management. This includes maintaining accurate and up-to-date supplier profiles, contact details, certifications and other relevant documentation.

- Manage and Reduce Risk: Suppliers may pose certain risks to an organization, such as financial instability, non-compliance with regulations or reputational risks. Supplier risk management involves assessing and mitigating these risks through due diligence, monitoring and contingency planning.

- Nurture Supplier Relationships: Building and nurturing strong relationships with suppliers is imperative for long-term success. Effective communication, collaboration and regular performance reviews are essential in fostering positive relationships and driving mutual value creation.

- Conduct Offboarding: At the culmination of a supplier’s lifecycle, offboarding activities are conducted. This may involve terminating contracts, transitioning to alternative suppliers or conducting exit interviews to gather feedback and identify areas for improvement.

Unlock the secrets to maximizing supplier performance and driving business success with Ivalua’s supplier management software. Watch the on-demand demo now!

5 Steps Toward Modernizing Supplier Management

Modernizing vendor management has become imperative for organizations seeking to stay competitive and resilient. The supplier lifecycle management process involves a strategic approach encompassing five essential steps:

- Gain control of your supplier data. Centralize and organize supplier data to ensure accuracy, completeness and accessibility. By consolidating supplier information into a single repository, organizations can enhance data quality, streamline processes and improve decision-making.

- Enable 360-degree visibility. Organizations should aim to have comprehensive visibility into all aspects of their supplier relationships, including performance, risk, compliance and interactions. This holistic view enables proactive risk management and the ability to identify opportunities for improvement.

- Map your Sub-tiers. By mapping sub-tiers, organizations can identify dependencies, assess risks and ensure continuity of supply. This visibility is crucial for managing supply chain disruptions and optimizing supplier relationships.

- Enable effective, scalable collaboration. Collaboration between internal stakeholders and suppliers is essential for driving mutual success. Implementing tools and processes that facilitate communication, information sharing and collaboration ensures effective collaboration across the supplier ecosystem. Make sure the solutions are scalable, so that collaboration processes can accommodate growth in your supplier base.

- Incentivize the right behavior. Implementing incentive programs or performance-based contracts can motivate suppliers to align their behavior with your organization’s goals and objectives. Consider rewarding desired outcomes such as quality, innovation and cost savings.

Watch Ivalua’s Supplier Management Software On-Demand Demo

What Are the Benefits of Supplier Lifecycle Management?

Ivalua’s Supplier Management Solutions are designed to revolutionize the way organizations handle their supplier interactions, yielding a spectrum of advantages that are tailored to maximize efficiency and magnify efficacy.

- Increased Visibility: Implementing a supplier lifecycle management program provides organizations with a comprehensive view of their supplier network, allowing for better decision-making and strategic planning.

- Improved Risk Management: Organizations who implement formal SLM processes can better monitor supplier performance, compliance and potential risks, and implement timely intervention and mitigation strategies.

- Cost Savings: Automating tasks associated with supplier-related processes such as supplier onboarding, qualification and performance evaluation can save organizations money and resources.

- Stronger Supplier Performance KPIs and Compliance: By monitoring supplier performance against established KPIs, organizations can identify areas for improvement, address any performance issues and ensure compliance with contractual obligations.

- Competitive Advantage: Supplier collaboration and innovation are essential for maintaining a competitive edge in the market. For example, Ivalua’s supplier portal provides a platform for sharing information, exchanging documents and conducting performance reviews, facilitating collaboration and innovation between organizations and their suppliers. This improved transparency and communication ultimately contributes to enhanced overall supplier relationships and a competitive advantage in the marketplace.

Best Practices for Creating a Strategic Supplier Management Strategy

Strategic supplier management is about creating a supply chain strategy that is not only strategic and forward-looking, but also capable of consistently delivering value, reducing risk, and enhancing performance.

Each organization has distinct needs, and achieving a top-tier status should never be hindered by technological constraints. When there’s a disconnect between supplier strategy and business strategy, it endangers both market share and overall profitability.

To avoid that disconnect, you can begin by implementing a best-in-class supplier relationship management program with few straightforward steps:

- Start by crafting tailored onboarding processes that strike the right balance between speed and risk. It’s important to set up a mechanism that facilitates communication and collaboration with your suppliers effectively.

- Integrating risk and performance evaluations into all your processes is crucial. This should be complemented by the regular monitoring and assessment of supplier performance to ensure standards are met. Digitizing supply chain collaboration can streamline these processes, making them more efficient.

- Lastly, maintaining a focus on data quality, consistency, and the pursuit of continuous improvement will drive the success of your supplier relationship management program.

Download our Supplier Risk and Performance Management Checklist to learn how you can get the most out of your SRPM program.

Chassis Brakes Transforms its Global Procurement and Supply Chain, With Ivalua

Chassis Brakes International was looking to leverage Supplier Lifecycle Management technology to develop more strategic supplier partnerships and global supplier coverage. Requirements included maintaining clean and centralized supplier master data and setting up KPIs for monitoring supplier performance. The company wanted to drastically increase PO coverage and visibility into contracts by digitizing and standardizing core practices such as PR/PO, RFQ and catalogs, for both direct and indirect spend.

However, with more than 12,000 suppliers across multiple SAP ERP instances, this was a huge challenge. Procurement contracts were stored locally, making access difficult. Inconsistent, manual processes meant global commodity managers had little control and visibility of supplier strategy.

With Ivalua’s Supplier Lifecycle Management software, Chassis Brakes reduced direct spend by 5% and indirect spend by about 10%, while reducing the supplier base by over 50%. They now have 99% PO coverage and 98% spend analyzed, as well as 100% procurement contract visibility. Ivalua’s solution also enabled them to implement mobile PR/PO approvals.

Ivalua has enabled our transformation journey effectively, making Procurement more agile and digital. It really began with a focus on suppliers and clean supplier master data to make better decisions. Resolving this empowered efficiency, visibility and much more value creation for the business.

Cyrille Naux, Vice President of Strategy, Operations and Procurement at Chassis Breaks

Read the full case study here: Why Chassis Brakes International chose Ivalua Supplier Management Software for Digital Procurement Transformation

How to Choose the Best Supplier Lifecycle Management Software

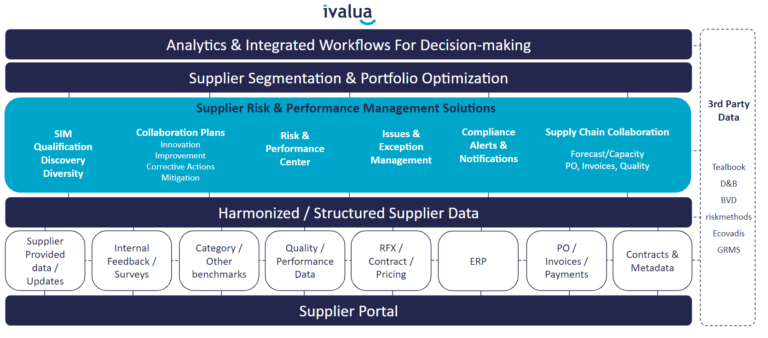

Ivalua has revolutionized the supplier onboarding process with its Supplier Management Solutions that effortlessly welcomes over a million suppliers into the global commerce network. The platform allows suppliers to get up and running in mere minutes, enabling immediate collaboration with buyers and maximizing productivity from the outset. Here’s a deeper look into the advantages:

360-Degree View of All Supplier Information

One of the key benefits of Ivalua’s Supplier Management Solutions is the 360-degree view of all supplier information. Organizations canaccess detailed profiles of their suppliers, including financial health, performance metrics, risk assessments, and compliance status. With all this information centralized and accessible, companies can make more informed decisions, identify potential risks early, and foster stronger, more productive relationships with their suppliers.

Comprehensive, Integrated Risk, and Performance Management

Ivalua’s solutions go beyond basic vendor lifecycle management–they integrate risk and performance management into a unified platform. This integration enables organizations to proactively manage and mitigate supplier risks while continuously monitoring and improving supplier performance. By having a clear understanding of both risk and performance factors, companies can anticipate potential issues, implement corrective actions promptly, and optimize their supply chain resilience.

Holistic Supplier Collaboration / Supplier Portal

Ivalua’s Supplier Portal facilitates holistic supplier collaboration and serves as a centralized platform for communicating with suppliers, sharing documents, and managing transactions. It enhances transparency and efficiency in the supplier relationship by allowing real-time updates, collaboration on documents, and streamlined processes for bidding, contracting, and invoicing. This level of collaboration helps in building trust and alignment between organizations and their suppliers, leading to more strategic and mutually beneficial relationships.

Further reading: Forrester named Ivalua as a leader in Supplier Value Management Platforms in its Forrester Wave™: Supplier Value Management Platforms, Q1 2022.

Conclusion

A strategic approach to supplier management is key to organizational success, and that includes the essential step of recognizing the crucial role of supplier lifecycle management software in enhancing procurement and supply chain outcomes. By adopting this software, businesses can streamline procurement processes, mitigate risks, improve supplier relationships, and enhance efficiency and transparency throughout the supply chain lifecycle.

Leverage Ivalua’s cutting-edge supplier lifecycle management software to future-proof your business against dynamic market fluctuations and the complexities of modern supply chains. With our robust suite of tools, you’ll not only address immediate concerns but also lay down a strong foundation for sustainable success and adaptability.

Experience firsthand how our comprehensive solutions can refine your supplier interactions by exploring our detailed supplier management demo today!