As businesses strive to meet the ever-increasing demands for quality, compliance and cost-effectiveness, the need for effective Supplier Performance Management (SPM) has become more crucial than ever. This process not only ensures a steady and reliable supply of materials but also plays a vital role in maintaining strong, mutually beneficial relationships with suppliers.

In this article, we’ll review the importance of ongoing Supplier Performance Management, steps and best practices for implementing SPM, and how technology can help to enhance and streamline this critical business function.

What Is Supplier Performance Management?

Supplier Performance Management is a business practice that focuses on assessing, monitoring and managing the performance of a company’s suppliers. This process is critical in supply chain management and procurement, as it directly impacts the quality, efficiency and cost-effectiveness of the supply chain.

SPM encompasses all the tools and practices a business uses to evaluate supplier performance. The goal is to understand vendor relationships so that the business can more effectively manage supplier risk, lower procurement costs and encourage positive supplier relationships. It also helps teams to resolve issues more efficiently and look for opportunities to improve.

SPM is crucial for maintaining high-quality standards, ensuring timely delivery and optimizing cost-effectiveness. By regularly assessing and managing supplier performance, businesses can identify and mitigate risks associated with supply disruptions or quality issues, maintain competitive pricing and foster strong relationships with their suppliers.

What Is The Difference Between SPM And SRM?

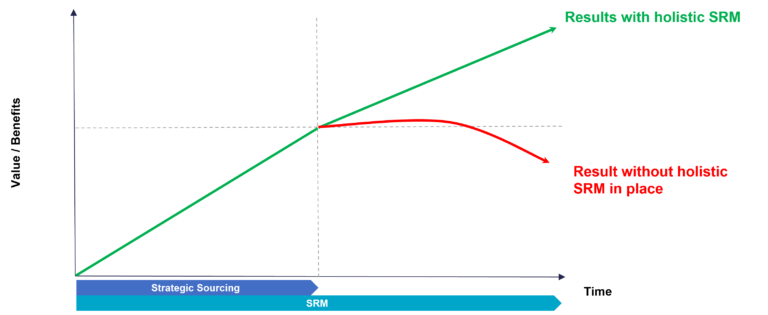

While SRM is about building and maintaining strong relationships with suppliers for long-term strategic benefits, SPM is more focused on the ongoing evaluation and improvement of supplier performance for immediate operational objectives.

Supplier Relationship Management is a comprehensive approach to managing and optimizing the interactions and relationships with suppliers. It’s strategic in nature and focuses on developing mutually beneficial relationships with key suppliers. SPM involves collaborative practices such as joint planning, shared objectives and often incorporates aspects like innovation and long-term value creation. It is about fostering positive, long-term relationships that are advantageous to both parties.

Supplier Performance Management , on the other hand, is more tactical and focuses specifically on measuring, analyzing and managing the performance of suppliers against defined benchmarks and KPIs. It involves the regular evaluation of suppliers to ensure they meet contractual obligations and performance standards, such as quality, cost, delivery time and compliance. SPM is largely about ensuring operational efficiency and effectiveness in the supply chain.

Both practices are integral to effective supply chain management.

Three Phases Of Supplier Performance Management

A structured approach to managing supplier performance ensures suppliers are meeting the organization’s expectations and contributing positively to the supply chain’s efficiency and effectiveness. Three critical phases include:

- Establishing KPIs: This phase involves setting clear expectations and defining the metrics or key performance indicators (KPIs) against which supplier performance will be evaluated. It usually includes establishing performance targets, aligning them with strategic goals, and agreeing upon them with the suppliers. This phase may also involve contract negotiations and finalizing service level agreements (SLAs).

- Monitoring and assessing performance: During this phase, the actual performance of suppliers is continuously monitored and assessed against the predefined metrics and targets. This involves collecting data on various aspects of supplier performance, such as quality, delivery timeliness, cost management, and compliance. Regular reviews and audits are conducted to evaluate supplier performance, identify areas for improvement, and ensure contract compliance.

- Continuous improvement: The final phase focuses on taking action based on the evaluation results. This includes providing feedback to suppliers, discussing areas of improvement, and collaboratively working on development plans to enhance performance. It can also involve revisiting and adjusting KPIs and targets to reflect any changes in business strategy or market conditions. The goal of this phase is to foster continuous improvement and strengthen the supplier relationship for long-term success.

Challenges In Supplier Performance Management

The overarching challenge of implementing supplier performance management lies in finding a way to timely monitor an increasingly global and diverse supply base at the appropriate level.Defining clear, relevant and measurable KPIs that align with business objectives and supplier expectations is critical.

However, the task of efficiently collecting and analyzing data to assess supplier performance and identify performance gaps is complex, especially when dealing with numerous suppliers, diverse product lines, and a disconnected information landscape. Ensuring data access, accuracy, and consistency remains a significant hurdle, as well.

Another challenge is making sure suppliers are not resistant to performance management or that they don’t consider the goals to be misaligned to their business. If the suppliers don’t consider the KPIs to be germane to the relationship or are cumbersome or unreasonable, they are not likely to participate. Effective performance management requires alignment and participation from both sides. Without this buy-in, supplier performance management is reduced to an ineffective tactical reporting exercise that is being done “to” supplier and not “with” them, and will not drive improvement.

Finally, Supplier Performance Management requires a significant amount of data across a large number of suppliers. This requires resources to implement and manage. Organizations may find challenges in locating and allocating the resources. This includes finding technology solutions to aggregate data, expose insights, and enable scalable processes and collaboration with suppliers.

What Happens when Supplier Performance Management Is Lacking?

Failing to implement Supplier Performance Management can have several negative consequences for a business:

- Quality Issues: Without effective SPM, there’s a higher risk of receiving subpar or inconsistent quality goods and services from suppliers. This can lead to product defects, customer dissatisfaction and damage to the company’s reputation. A reluctance to implement performance-based scorecards can result in inefficient, decentralized reporting and lack of senior-level involvement with supply quality management, as well.

- Supply Chain Disruptions: Without regular supplier performance monitoring and assessment, businesses are less prepared to identify and address potential supply chain disruptions, leading to stock shortages, production delays and, ultimately, lost sales and revenue.

- Increased Costs: Lack of supplier performance management practices can result in inefficiencies or over-reliance on certain suppliers, or a failure to negotiate better terms

- Compliance and Legal Risks: In industries where regulatory compliance is critical, not managing supplier performance can result in compliance failures. This can lead to legal penalties, fines and, in extreme cases, a loss of operating licenses.

- Missed Opportunities: Good supplier performance management can facilitate collaboration and innovation with suppliers. Without it, companies might miss out on opportunities for product improvements or new product offerings.

- Damaged Relationships with Suppliers: Good supplier relationships are based on mutual understanding and clear communication. Without supplier performance management, misunderstandings and lack of feedback can strain these relationships.

What Are the Key Steps to Monitor Supplier Performance?

Monitoring supplier performance is a systematic process. Here are the steps:

- Establish Performance Metrics: Begin by defining clear and measurable Key Performance Indicators (KPIs) for each supplier. These KPIs should align with your business objectives and can include metrics like quality, delivery time, cost, responsiveness, and compliance. Use the KPIS to establish performance benchmarks and targets and ensure these KPIs are communicated with suppliers and they are endorsing them. .

- Collect and Analyze Data: Implement a system for regularly collecting data on supplier performance. This can be done through various means such as supplier scorecards, automated tracking systems, or regular reporting by suppliers.

- Conduct Regular Performance Reviews: Performance evaluation should be a consistent process, done at agreed intervals (e.g., monthly, quarterly, annually), to assess if suppliers are meeting the set benchmarks and targets.

- Provide Feedback: Highlight areas where they meet or exceed expectations and discuss areas needing improvement. Open and transparent communication is crucial for effective supplier relationship management.

- Collaborate to Improve: If a supplier is underperforming, work collaboratively to develop an improvement plan. This plan should outline clear steps to address specific performance issues and set timelines for achieving improvements.

- Monitor Progress: Continuously monitor the supplier’s progress against the improvement plan. Regular check-ins and updates can help ensure the plan is being followed and the desired improvements are being made.

- Document Everything: Keep detailed records of all performance reviews, communications, improvement plans and outcomes. This documentation is vital for future reference and decision-making.

Technology and Best Practices for Effective Supplier Performance Management

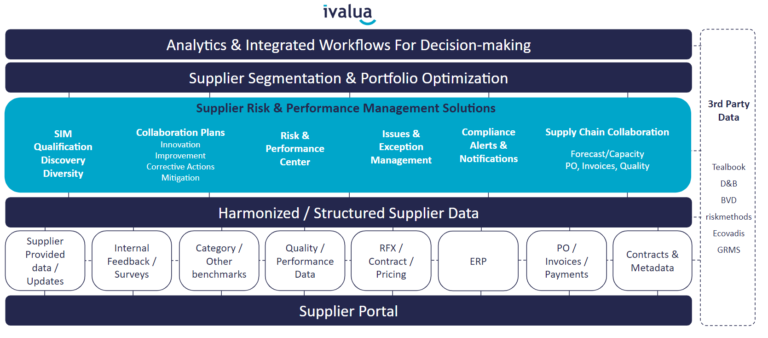

Technology solutions such as Ivalua’s Supplier management software play a pivotal role in streamlining and enhancing the process of supplier performance monitoring. Such advanced software and digital tools can automate the collection and analysis of performance data, ensuring accuracy and consistency in tracking key performance indicators (KPIs). They facilitate regular performance reviews by aggregating data in real-time, providing actionable insights into supplier metrics.

Additionally, technology enables effective communication and feedback mechanisms, allowing for prompt and transparent interactions with suppliers. It supports collaborative efforts in creating and monitoring improvement plans, with platforms for shared access to documents and progress tracking.

What’s more, technology aids in maintaining comprehensive and organized records of all supplier-related activities and communications, essential for future evaluations and decision-making. Take a look at what Deloitte has to say about how digitization in supply chain management is impacting supplier performance management in their Supply Chain report.

Essential Metrics for Supplier Performance Evaluation

Here are some key performance indicators for supply chain management:

- Quality metrics: Defect rates, product conformity, and customer satisfaction

- Delivery metrics: On-time delivery, lead time, and order fulfillment accuracy

- Cost metrics: Price competitiveness, cost savings, and total cost of ownership

- Relationship metrics: Communication, responsiveness, and collaboration

Regional Medical Provider Benefits from Supplier Performance Management with Ivalua

Select Medical is a regional provider of outpatient physical rehabilitation. The organization faced numerous procurement challenges, including decentralized processes, a lack of corporate oversight, and a lack of detailed purchasing data. Invoice approvals were slow and cumbersome, as well. These challenges were costing the organization money.

Using Ivalua’s Supplier Management software, Select Medical realized multi-million savings. Not only did they digitize the full P2P process, they implemented touchless processing of over 360,000 invoices and more than 263,000 purchase orders, and can now manage more than 10,000 contracts digitally. Read the full case study.

Optimizing The End-to-End Value Chain through an Integrated Solution

Ivalua’s supplier performance management software provides comprehensive, integrated and user-friendly tools that help optimize the value chain end-to-end. It improves supplier performance monitoring and visibility, risk management and collaborative engagement, all of which are essential for a resilient and efficient supply chain.

Ivalua’s platform acts as a centralized repository for all supplier-related information, including contracts, performance data, risk profiles and compliance documents. The solution allows for the tracking and evaluation of supplier performance against predefined KPIs, and it automates data collection and analysis. Contract management features enable companies to manage the entire lifecycle of contracts efficiently.

Importantly, Ivalua’s solution integrates seamlessly with other procurement processes such as sourcing, procurement and invoice management, ensuring that supplier performance data is reflected across the procurement cycle. This integration enables a more strategic, holistic approach to procurement and supply chain management. Watch a demo of Ivalua’s Supplier Management solution.

Elevate Supplier Performance

The ongoing management of supplier performance is a critical component for maintaining a resilient, efficient and competitive supply chain. Consistent supplier performance monitoring and evaluation mitigates risks associated with supply disruptions and fosters strong, collaborative supplier relationships, leading to improved performance and innovation.

Ivalua provides powerful and adaptable supplier performance management software for businesses seeking to elevate their supplier performance management to new heights of efficiency and effectiveness. The comprehensive and integrated platform offers centralized data management, robust performance monitoring tools, effective risk management and seamless integration with other procurement processes.

Learn more about the solution and download Ivalua’s Supplier Risk and Performance Management Checklist today.