Ivalua Named A Leader In The 2025 Gartner Magic Quadrant™ For Source-To-Pay Suites Report

View Report

Ivalua Named A Leader In The 2025 Gartner Magic Quadrant™ For Source-To-Pay Suites Report

View Report

Blog »

The Pixar building is one of the most vivid examples of how successful companies value cross functional collaboration within their organisation. The building was originally planned by Steve Jobs as three separate buildings for the computer scientists, animators and executives at Pixar; but he realised that the building layout could maximise the collaboration between all different parts of the organisation.

This was delivered initially by having a sizeable atrium in the centre of the single office building to enable people to communicate, which it was assumed would lead to greater collaboration. Jobs did not stop there and added areas to the atrium to bring people to this part of the building, with mailboxes, meeting rooms, cafeteria, coffee bar and eventually a gift shop.

Through these times of covid with long periods of home working required for many workers, I am sure there is a greater understanding of the value of collaboration with colleagues. As well as the mental health benefits, the ad-hoc conversations over a sandwich or before a meeting starts can lead to great ideas being put into action.

At a recent roundtable with The Manufacturer magazine, the benefits of cross functional collaboration for procurement was raised as a discussion point for the session.

Efficio, the procurement consultancy very kindly joined in the roundtable discussion and Simon Lipscomb from Efficio gave some great insight into this area from the Profit from Procurement book that the Efficio have recently published.

The book gives a clear view of the benefits of cross functional collaboration for procurement and also some actionable insights as to how procurement can foster collaboration with other areas of the business.

One of the most interesting suggestions is that a procurement team should take a service mindset when working with the budget holders within the organisation. By supporting the budget holders they can then deliver value to the organisation.

Ivalua’s view point in this area is that procurement has struggled to deliver value through cross functional collaboration due to some specific challenges, especially in organisations in manufacturing, automotive, defence and aerospace, where direct spend is significant and critical.

Ivalua has many customers who are optimizing their direct spend and generating value, but we’ve also talked to many other organisations in this sector who are not able to transform their procurement function to deliver more value.

One of the main issues within such verticals is that the transformation focus has been primarily on indirect from a procurement standpoint, largely due to technology providers not being able to address both indirect and direct spend processes.

Within manufacturing organisations direct spend is often a large % of spend, up to 80% with indirect being the remainder. This means that the financial benefits that are being missed are quite significant, along with (and maybe more importantly) the non-financial factors, such as reducing supplier risk or utilising supplier innovation to increase performance.

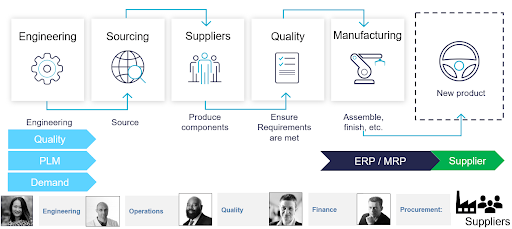

Many procurement functions are struggling to deliver cross functional collaboration and one of the factors that Ivalua has identified is the access that procurement has to data in third party systems. As an example, procurement can deliver significant benefits to a new product introduction by being engaged with the process at the earliest stages.

If procurement is unable to utilise the Bill of Material (‘BoM’) data in the PLM system that the Engineering team are utilising to develop the new product, then the barriers to collaboration are clear.

One of the examples raised in a previous roundtable was that the procurement team of a large defence manufacturer had to work closely with the operations team during covid to reconfigure the supply chain, as suppliers were unable to deliver.

It is true to say that technology is not solely the answer to these types of challenges, but Ivalua feels that tackling this issue of connectivity is key to unlocking the value of procurement, especially in the more complex environment of direct spend. By being able to import BoM data into Ivalua from a PLM or MRP system means that procurement has the capability to deliver value and truly collaborate with suppliers.

The other key element in this area is that procurement solutions like Ivalua can automate much of the tactical work that procurement teams need to deliver and there are obvious efficiency benefits, but this also frees up time for the procurement team to focus on more strategic activities, such as identifying opportunities for suppliers to deliver supplier innovation.

Ikea is an Ivalua customer – managing direct spend through our platform and working with its supplier community to inject innovation into their product range, such as the Misteln tap nozzle that saves water and was developed in conjunction with Altered, one of Ikea’s Swedish suppliers, or the audio furniture developed in conjunction with Sonos.

As demonstrated by the feedback from a section of large manufacturing companies that participated in the roundtable, the development of procurement functions in achieving this cross functional collaboration is mixed.

Some organisations are still focused on their role of compliance within the organisation, which is important but does restrict collaboration and other organisations were clearly delivering benefits through high levels of collaboration.

Due to the impact of covid on organisations, especially in areas with high levels of direct spend such as industrial manufacturing, automotive and defence, there is now greater understanding within organisations around the benefits of procurement closely collaborating with other parts of the organisation.

Along with this shift in understanding, if procurement can develop how they engage with the business and look at key areas such as their operating model, then cross functional collaboration is in reach for most companies. Technology does play a part, giving procurement advanced tools to deliver value, but also more importantly connecting these tools to the third party data that is being used by the other parts of the business.

By giving access to this data and thus access to the working of departments such as engineering, operations and quality, procurement can collaborate effectively, proving the value of procurement within the wider organisation.

Stephen Cleminson is the Alliances Director at Ivalua. He’s responsible for recruiting and managing a partner network across Northern Europe and brings experience of over a decade in commercial roles at a number of P2P vendors. Stephen has built a comprehensive understanding of the benefits and challenges of P2P technology from his close involvement in a variety of projects for large multi-national organisations.

Stephen’s experience was initially in the use of P2P solutions for indirect spend, but Ivalua’s strengths in direct materials procurement has expanded his knowledge and expertise to this important operational area.