Build Stronger Supply Chains with Better Supplier Collaboration

Direct Material Sourcing and Supply Management processes are often manual and non-standard. As a result, organizations suffer from poor responsiveness to supply disruptions, inefficiencies that limit scale, and sub-optimal supply planning.

Manage Total Costs, Ensure Supply Continuity

Ivalua’s purpose-built Direct Materials Sourcing and Supply Chain Collaboration solutions manage total costs throughout a product’s lifecycle to maintain supply continuity, improve margins, and enhance supply chain agility.

Unlock Profitability and Growth

Launch Profitable Products

- Supplier collaboration across product lifecycle

- Achieve product cost targets

- Efficient new product launch processes

Ensure Supply Continuity

- Approve demand forecasts with suppliers

- Optimize supply chain order efficiency

- Digital and transparent supply chain transactions

Collaborative Supply Chain

- Seamless integration with ERP/MRP

- Extend collaboration to stakeholders and suppliers

- Automate and streamline processes

After a comprehensive evaluation of many leading vendors, we selected Ivalua. Their approach has been that of a true partner. And the Ivalua platform enables us to manage all major sourcing activities [direct and indirect] in one place, driving standardization and supplier data harmonization across our global businesses.

Michael Stietz

SVP & Chief Procurement Officer

Körber

Why Manage Direct Spend?

Effective Direct Spend Management Collaboration is critical to product launch performance, and by extension–the success of your organization. Ivalua’s Direct Materials Solutions serve as the collaborative bridge with suppliers to create profitable products and improve supply continuity.

Automation Benefits

Direct Materials Procurement Automation Benefits:

- Reliable material and product supply

- Managed supplier risk, performance, and quality

- Revenue growth and increased innovation

- Improved margins

A Unified Platform for All Spend

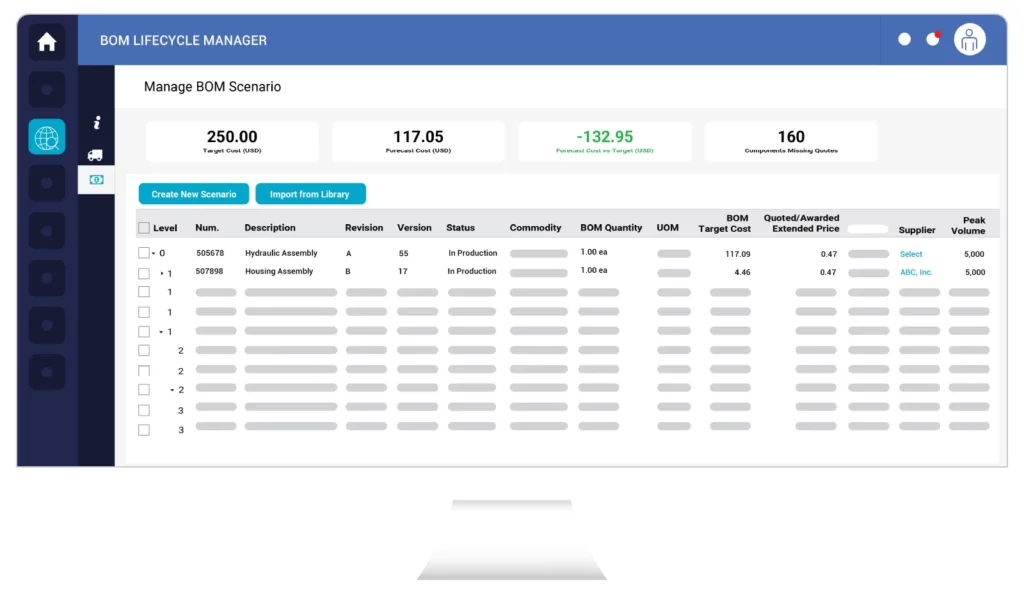

Direct Materials Sourcing

Maximize Strategic Sourcing Outcomes and Improve Product Launch Success

- Achieve target costs and optimize supplier selections

- Manage complex BOM and cost breakdowns

- Improve product launch success and quality

- End-to-end Spend Management

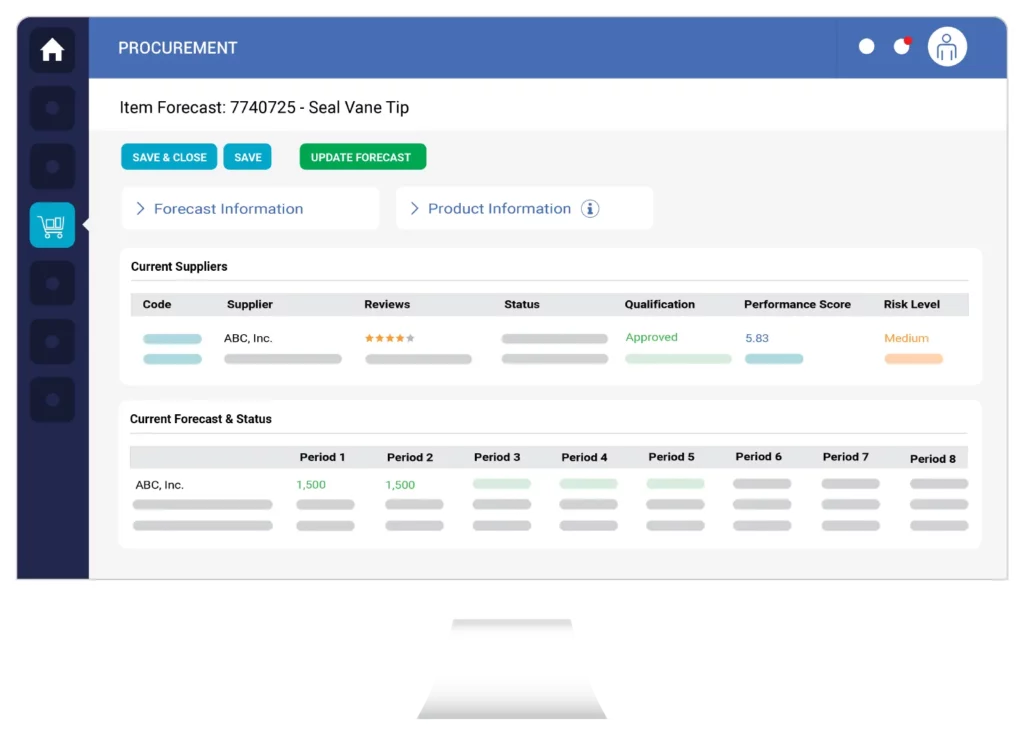

Supply Chain Collaboration

Secure your Supply Chain and Reduce the Risk of Disruption

- Automated supplier communication and collaboration

- Share material and capacity forecasts

- Optimize supply chain order efficiency

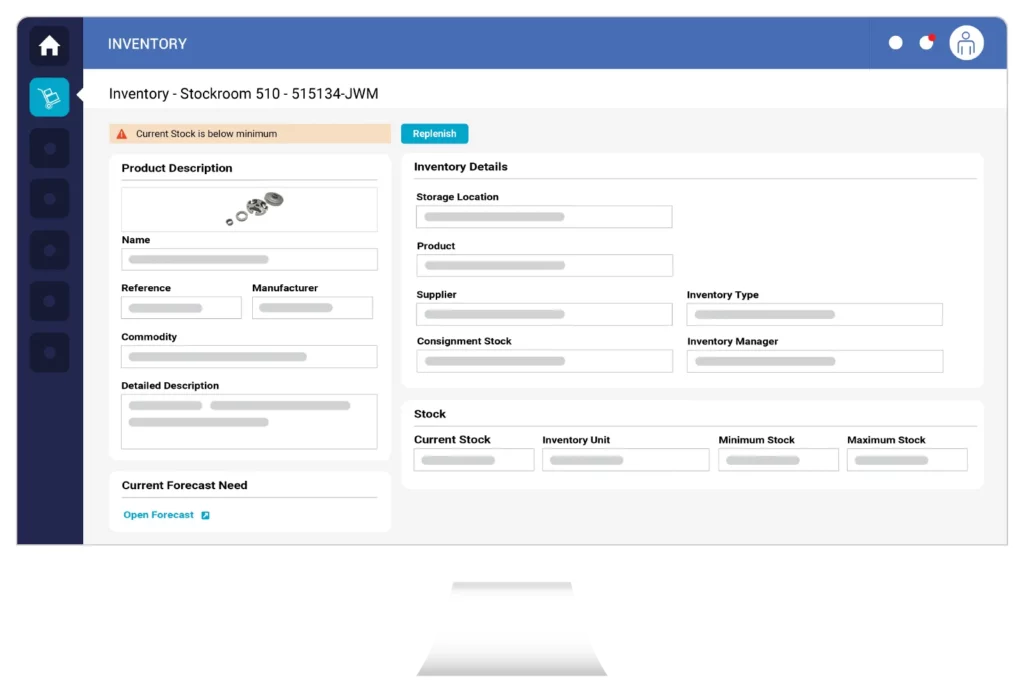

Inventory Collaboration

Optimize Inventory & Working Capital

- Anticipate potential shortages and stock outs

- Auto-calculate replenishment needs

- Share forecasted demand with suppliers

- Visibility and control for vendor managed inventory (VMI)

- Share preferred storage locations and availability